Mining Rock Ore Grinding Ball Mill Powder Mesin Penggilingan

Ball mill minangka piranti utama kanggo grinding. Iki digunakake kanthi akeh kanggo semen, produk silikat, bahan bangunan jinis anyar, materi tahan geni, pupuk kimia, logam ireng lan non-ferrous, kaca, keramik lan liya-liyane.

Pabrik werni cocok kanggo beneficiation lan mecah awu fly, watu gamping, wedhi kuarsa, bubuk aluminium, bubuk batu bara, slag baja, bijih, kalium feldspar, bijih wesi, slag wesi, slag aluminium, silikon karbida, alumina, gangue batu bara lan bahan liyane.

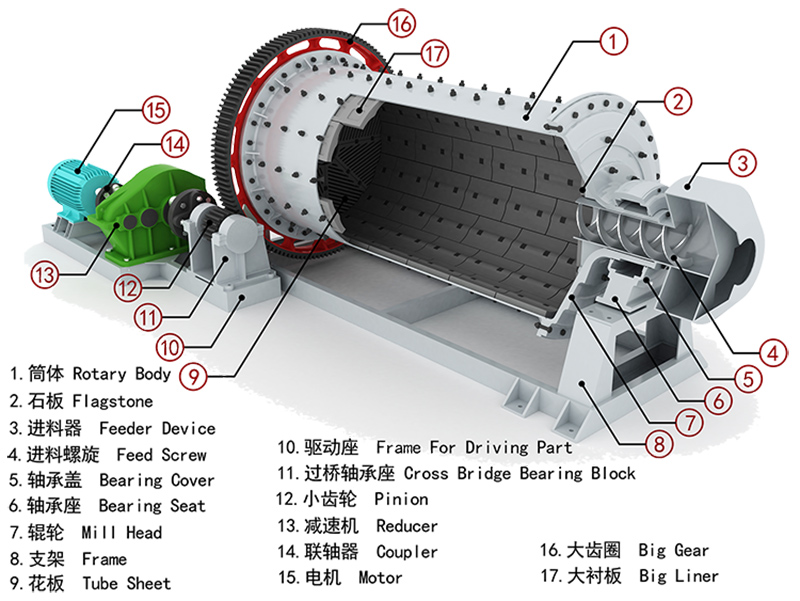

Prinsip Kerja

Bagean utama pabrik werni udan yaiku silinder kanthi diameter cilik lan dawane muter alon-alon dening piranti transmisi. Materi kasebut dipangan saka inlet silinder lan lemah kanthi pengaruh bal baja lan bijih lan grinding dhewe. Amarga bahan pakan sing terus-terusan, tekanan nyurung materi menyang stopkontak lan materi lemah dibuwang saka stopkontak silinder. Kothak sing dipasang ing stopkontak pabrik diandelake kanggo discharge paksa. Lumahing pulp kurang ing silinder nyuda bijih liwat-mecah, lan nyegah werni baja metu. Ing kahanan produksi sing padha, kapasitas produksi pabrik kothak luwih gedhe tinimbang pabrik overflow. Loro-lorone ujung awak silinder nganggo bantalan rolling tinimbang bantalan geser, sing luwih hemat energi.

Spesifikasi Teknis

| Jinis | Kacepetan rotasi | Bobot bal | Ukuran pakan | Ukuran output | Kapasitas | daya motor | Bobot |

| Ф900×1200 | 36 | 1.0 | ≤20 | 0.074-0.4 | 0.5-1.5 | 18.5 | 4 |

| Ф900×1800 | 36 | 1.5 | ≤20 | 0.074-0.4 | 1.1-3.5 | 22 | 4.8 |

| Ф900×3000 | 36 | 2.6 | ≤20 | 0.074-0.4 | 1.5-4.8 | 30 | 6 |

| Ф1200×2400 | 31 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 30 | 9.5 |

| Ф1200×4500 | 31 | 6.5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 4.5 | 13.1 |

| Ф1500×3000 | 27 | 6.8 | ≤25 | 0.074-0.4 | 2-6.3 | 75 | 16 |

| Ф1500×4500 | 27 | 10 | ≤25 | 0.074-0.4 | 3-9 | 110 | 19 |

| Ф1500×5700 | 27 | 13 | ≤25 | 0.074-0.4 | 3.6-11 | 130 | 24 |

| Ф1830×3000 | 25 | 10 | ≤25 | 0.074-0.4 | 4-11 | 130 | 25 |

| Ф1830×3600 | 25 | 12 | ≤25 | 0.074-0.4 | 4.3-12 | 155 | 32 |

| Ф1830×4500 | 25 | 15 | ≤25 | 0.074-0.4 | 4.5-16 | 155 | 33.7 |

| Ф1830×6400 | 25 | 21 | ≤25 | 0.074-0.4 | 6-17 | 210 | 38 |

| Ф1830×7000 | 25 | 23 | ≤25 | 0.074-0.4 | 6.5-18 | 210 | 43 |

| Ф2100×3000 | 23 | 13 | ≤25 | 0.074-0.4 | 5-15 | 180 | 32 |

| Ф2100×3600 | 23 | 16 | ≤25 | 0.074-0.4 | 6-17 | 210 | 35.8 |

| Ф2100×4500 | 23 | 20 | ≤25 | 0.074-0.4 | 7-21 | 245 | 42.6 |

| Ф2100×7000 | 23 | 31 | ≤25 | 0.074-0.4 | 8-25 | 280 | 55 |