Emas Tembaga Ore Stone Ball Mill Mesin Grinding Mill

Ball mill punika peralatan tombol kanggo mecah sawise proses crushing ing tanduran beneficiation, kang digunakake kanggo nggiling jinis bahan kayata bijih tembaga, bijih emas, bijih magnetite, kuarsa, bijih seng timbal, feldspar lan bahan liyane menyang wêdakakêna nggoleki 20-75micrometer. Adhedhasar jinis discharging, Bisa uga jinis grate, jinis kebanjiran, lsp. Apa maneh, pabrik bal bisa digunakake kanggo grinding garing lan teles kanggo kabeh jinis bijih lan bahan sing bisa digiling. Model pabrik bola penjualan panas yaiku 900 * 1800, 900 * 3000, 1200 * 2400, 1500 * 3000, lsp.

Prinsip Kerja Ball Mill

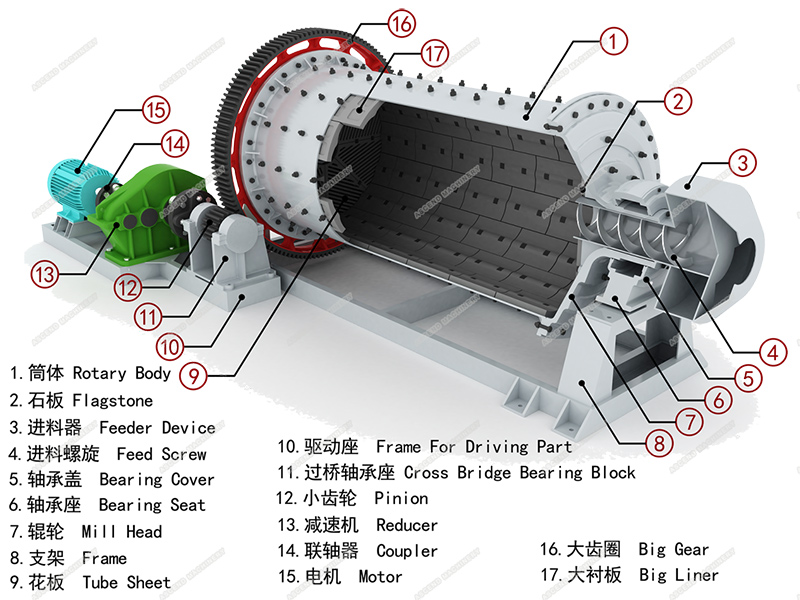

Pabrik werni iku piranti rotasi silinder horisontal, nyopir kanthi gearwheel brim, ana rong kamar lan kothak. Material dadi menyang kamar pisanan liwat welingan dipakani, nang kamar pisanan, ana liners tataran lan ripple liners uga bal baja karo macem-macem kinds.The Nihan muter kang njedulake eccentricity, pasukan iki ndadekke bal menyang dhuwur tartamtu lan banjur bal nyelehake mudhun dening gravitasi, kang bakal impact lan tlatah materi. Sawise mecah utami ing kamar pisanan, materi dadi menyang kamar kapindho liwat layar misahake, ing kamar liya, ana Fiat liners lan bal baja, sawise mecah secondary, materi wis kosong liwat layar discharge.

Rincian Ball Mill

Spesifikasi Ball Mill

| Model | Kacepetan rotasi cangkang (r/min) | beban bal (t) | Ukuran pakan (mm) | Ukuran discharging (mm) | Kapasitas (t/h) | daya motor (kw) | Total bobot (t) |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0,075-0,89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0,075-0,89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0,075-0,6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

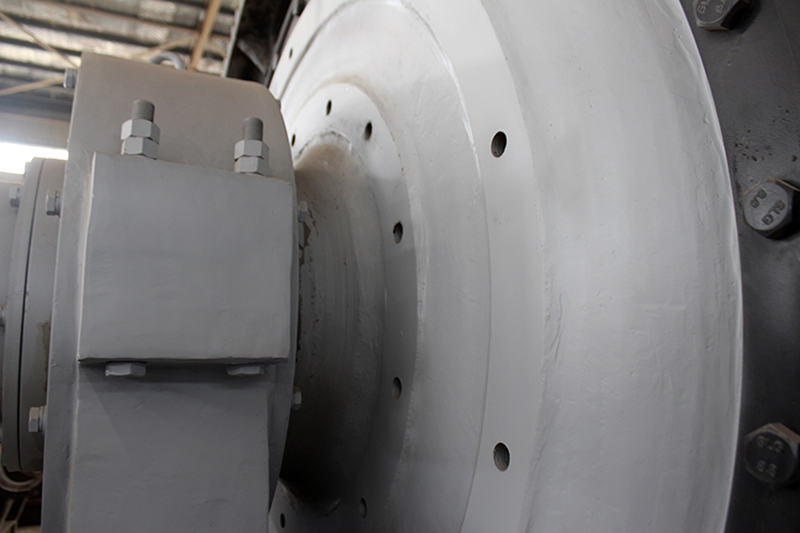

Spare Parts Ball Mill

Kanggo ball mill, suku cadang utama yaiku bal baja, liner ball mill lan piring grate. Yen customer perlu liners werni lan piring grate, padha bisa ngirim kita drawing liners lan grate piring, kita bisa matak kanggo wong-wong mau ing pabrik casting kita. Yen sampeyan ora duwe data liner, kita bisa ngirim insinyur menyang situs sampeyan lan ngukur liner, banjur kita bisa nggawe gambar lan nyithak liner ing pabrik pengecoran kanggo sampeyan.